Electrifying Efficiency: Unleashing the Power of Proper Grounding in ESD Flooring

In a world driven by technology, where static electricity can wreak havoc on delicate electronic components, the importance of proper grounding cannot be overstated. Imagine this scenario: you’re working in a high-tech laboratory, surrounded by state-of-the-art equipment worth millions of dollars. Suddenly, a spark of static electricity jumps from your fingertips and zaps a crucial circuit board, rendering it completely useless. The frustration and financial loss that ensues are not only devastating but completely preventable with the right measures in place. This is where ESD flooring comes into play. ESD, or Electrostatic Discharge, can cause irreparable damage to sensitive electronic devices. From manufacturing facilities to data centers, static electricity poses a significant threat to the integrity and functionality of our modern-day technologies. That’s why businesses and organizations around the world invest in ESD flooring – a specialized type of flooring specifically designed to dissipate static charges and maintain a controlled electrostatic environment. But the true power lies not only in the flooring itself but in the proper grounding techniques employed alongside it.

In this comprehensive blog post, we will delve into the intricate details of ESD flooring and explore how grounding plays a pivotal role in maximizing its effectiveness. From understanding the principles behind static electricity to dissecting the various types of ESD flooring available, we will equip you with the knowledge and tools necessary to protect your precious electronic investments. So, fasten your seatbelts, because we’re about to embark on an exhilarating journey through the electrifying world of ESD flooring and the electrifying power of proper grounding.

The Role of Grounding in ESD Protection

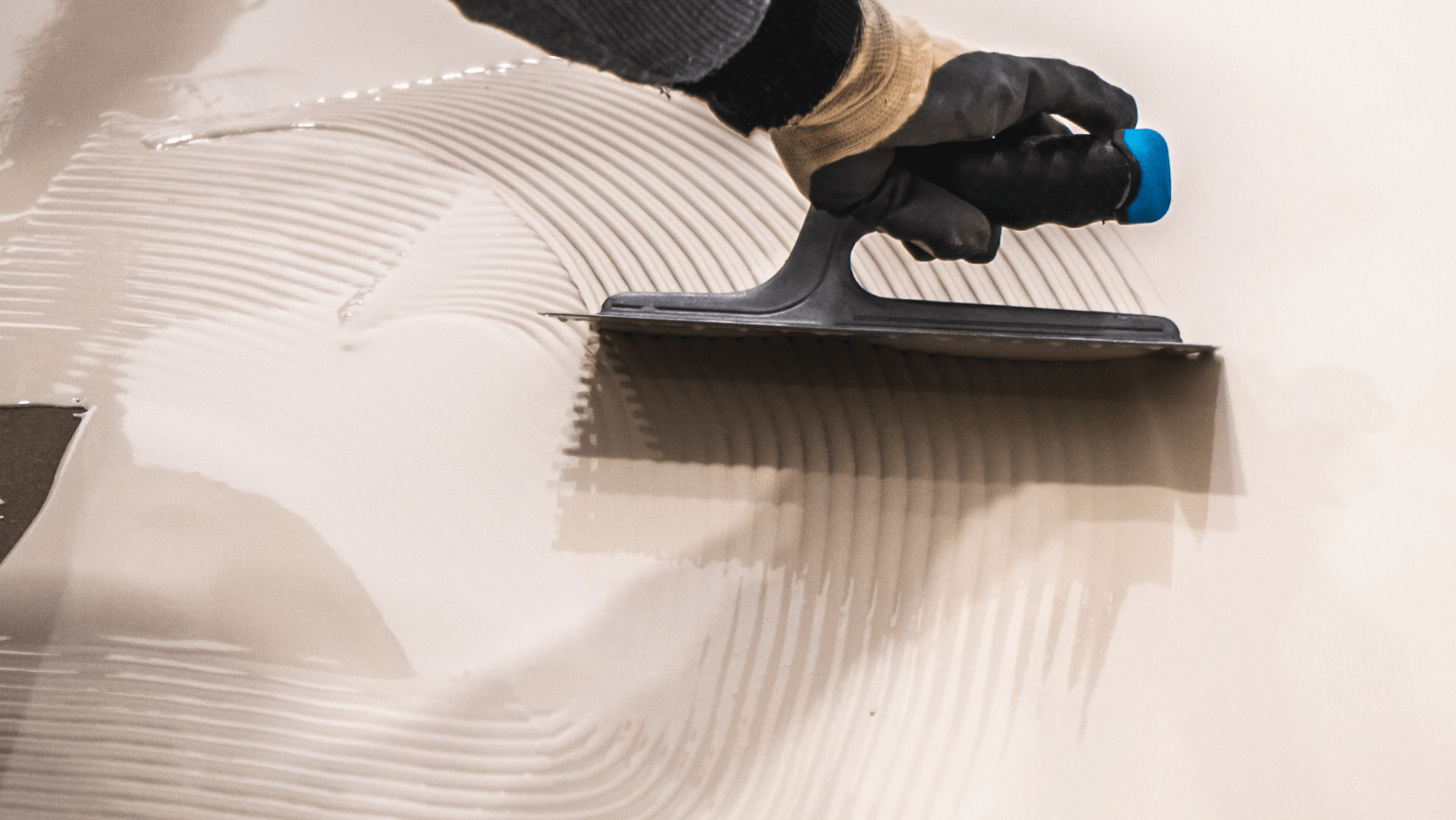

Proper grounding is the backbone of any effective ESD protection system. Without it, even the most advanced ESD flooring will be rendered ineffective. Grounding serves two primary purposes in ESD protection: it provides a path for static charges to safely dissipate and prevents the buildup of static electricity on surfaces.When an object becomes charged with static electricity, it seeks to discharge that energy to its surroundings. Without a proper grounding system in place, this discharge can occur through sensitive electronic components, causing damage or complete failure. By providing a low-resistance path to ground, grounding ensures that any static charges are safely redirected away from critical equipment.In an ESD flooring system, grounding is achieved through a combination of conductive materials and specialized techniques. Conductive materials such as copper strips or conductive adhesives are used to establish a direct connection between the flooring and a designated ground point. This connection allows any static charges accumulated on the flooring surface to be quickly dissipated.

One common technique used for grounding in ESD flooring is known as “point-to-point” grounding. This method involves connecting each individual conductive tile or panel directly to the ground point using copper strips or wires. By creating multiple grounded points throughout the flooring system, point-to-point grounding ensures an even distribution of static charge dissipation. Another technique commonly employed is known as “grounding grid” or “grid-style” grounding. In this approach, conductive tiles or panels are interconnected using conductive adhesive or copper strips to form a grid pattern. The entire grid is then connected to the ground point, creating a network that allows for efficient dissipation of static charges across the entire floor area.Regardless of the specific grounding technique used, regular maintenance and testing are essential to ensure its effectiveness.

Over time, factors such as wear and tear, contamination, or improper installation can compromise the integrity of the grounding system. Routine inspections and testing should be conducted to identify any potential issues and address them promptly.In conclusion, proper grounding is a critical component of any ESD protection system, especially when it comes to ESD flooring. It provides a safe path for static charges to dissipate and prevents the buildup of static electricity on surfaces. By implementing the right grounding techniques and regularly maintaining and testing the system, businesses can unleash the full power of their ESD flooring and protect their valuable electronic investments. So, remember to stay grounded and keep your technology electrifyingly efficient!

Surface Technology is a licensed industrial resin and epoxy flooring contractor, able to complete projects anywhere in the United States. We work with facility owners, design-build firms, construction management firms, and general contractors to provide industrial flooring solutions for projects in the range of 1,000 to 1,000,000+ square feet. Since 1988, we have over 35+ Years in business specializing in industrial flooring and commercial flooring services for Food and Beverage Processing, Manufacturing, Warehouse, FDA Compliance, Aircraft hangar, Vehicle Maintenance and Storage, and Pharmaceutical industries. We are experts in providing abrasion-resistant, no-slip, FDA-approved flooring for businesses.