Reviving Warehouse Floors: Conquering Challenges in Busy Industrial Environments

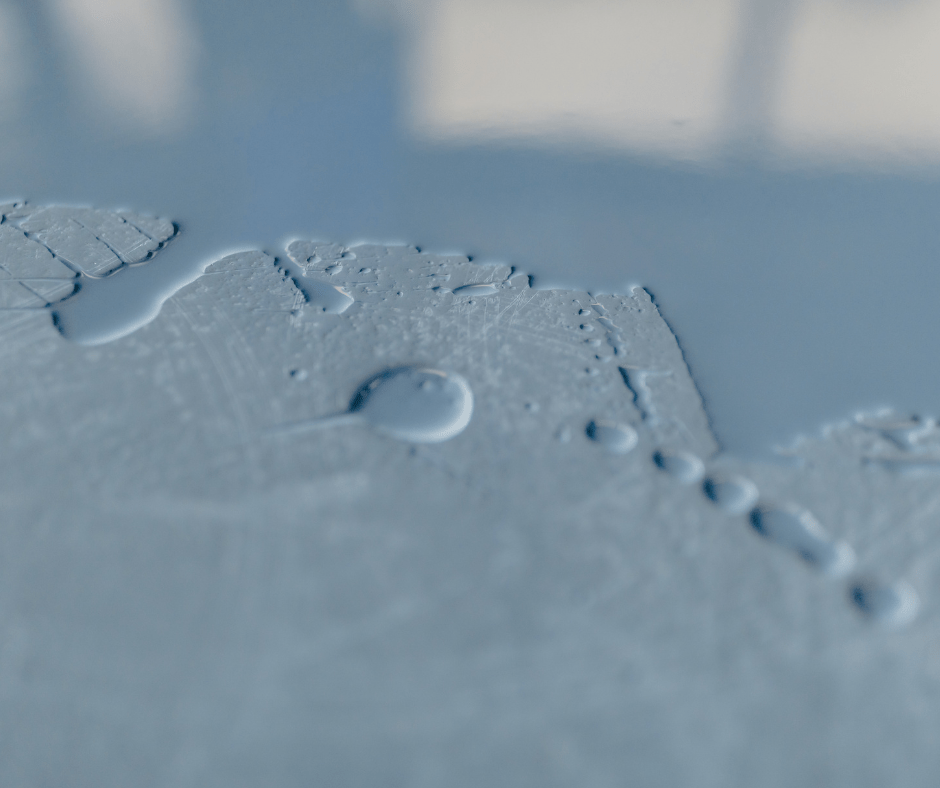

Walking into a bustling warehouse, the sights and sounds can be overwhelming. Forklifts whizzing by, pallets stacked high, and workers hustling to meet deadlines – it’s an environment that demands efficiency and productivity. But amidst the constant activity, one crucial element often goes unnoticed: the warehouse floor. Although it may seem like just a simple surface, the condition of the warehouse floor can significantly impact operations and worker safety. That’s where the process of warehouse floor resurfacing comes into play, providing a solution to the challenges faced in these busy industrial environments. In the world of logistics, time is money, and any downtime due to floor repairs can be costly. However, as the floors endure heavy traffic, they gradually become worn and damaged, posing potential hazards. Cracks, potholes, and uneven surfaces can lead to accidents, slowing down operations and incurring additional expenses. To tackle these challenges head-on, warehouse owners and managers are turning to the art of warehouse floor resurfacing. Warehouse floor resurfacing is a specialized process that involves repairing and restoring the floor to its original function and appearance, while also enhancing its durability to withstand the rigorous demands of the industrial environment.

By applying advanced techniques and high-quality materials, resurfacing experts can transform even the most worn-out floors into smooth, level surfaces that can endure heavy loads and constant movement. From small patches to complete resurfacing projects, the process aims to revitalize warehouse floors, ensuring optimal functionality and safety. When it comes to warehouse floor resurfacing, however, not all environments are created equal. Busy industrial settings present unique challenges that require a tailored approach. The resurfacing process must be carefully planned and executed to minimize disruption to daily operations and maximize efficiency. In this blog post, we will delve into the complexities of conquering challenges in busy industrial environments and explore the innovative techniques and strategies employed in warehouse floor resurfacing.

So, buckle up and get ready to discover how this essential process can breathe new life into warehouse floors, optimizing productivity and creating a safer working environment.

Assessing the Condition of the Warehouse Floor

Before embarking on any warehouse floor resurfacing project, it is crucial to assess the condition of the existing floor. This assessment helps determine the extent of damage and the appropriate course of action to restore and enhance the floor’s functionality.

The first step in assessing the condition of the warehouse floor is conducting a thorough inspection. Resurfacing experts examine every inch of the floor, looking for signs of wear and tear, cracks, potholes, and uneven surfaces. They also take into account factors such as moisture levels, chemical exposure, and temperature fluctuations that can affect the performance and longevity of the new surface.

During this assessment process, resurfacing professionals may use specialized tools such as moisture meters, laser levels, and concrete hardness testers to gather accurate data about the floor’s condition. This data helps them develop a comprehensive plan for addressing specific issues and selecting suitable materials for resurfacing.

By conducting a detailed assessment, warehouse owners and managers can make informed decisions about whether to opt for minor repairs or undertake a complete resurfacing project. It also allows them to anticipate any potential challenges that may arise during the process.

Selecting the Right Materials for Warehouse Floor Resurfacing

The success of any warehouse floor resurfacing project depends on selecting high-quality materials that can withstand heavy traffic and provide long-lasting durability. With numerous options available in today’s market, it is essential to choose materials that are specifically designed for industrial environments.

Epoxy coatings are one popular choice for warehouse floor resurfacing due to their exceptional strength and resistance to chemicals, abrasion, impact, and heavy loads. These coatings create a seamless surface that is easy to clean and maintain while enhancing safety by providing slip-resistant properties.

Another material commonly used in warehouse floor resurfacing is polyurethane concrete. This material offers excellent resistance to thermal shock, making it ideal for environments with extreme temperature fluctuations. Polyurethane concrete also provides superior impact resistance and can withstand heavy loads, making it a reliable choice for busy industrial settings.

When selecting materials, it is crucial to consider factors such as the specific needs of the warehouse, the type of traffic it experiences, and any unique requirements or regulations. Consulting with resurfacing experts can help ensure that the chosen materials are suitable for the specific challenges faced in busy industrial environments.

Planning the Resurfacing Project: Minimizing Downtime and Disruption

In a busy industrial environment, minimizing downtime and disruption is paramount. Warehouse floor resurfacing projects must be carefully planned to ensure that operations can continue as smoothly as possible during the process.

The first step in planning a resurfacing project is determining the most appropriate time for execution. This often involves coordinating with warehouse managers to identify periods of lower activity or scheduled shutdowns when operations can be temporarily relocated or scaled back.

Once a timeline has been established, resurfacing experts develop a detailed plan that outlines each step of the project. This plan includes factors such as surface preparation, application of materials, curing time, and any necessary safety measures.

To minimize disruption further, some advanced techniques can be employed during the resurfacing process. For example, fast-curing materials can significantly reduce downtime by allowing areas to be reopened for traffic within hours rather than days. Additionally, using dust-free equipment and implementing proper ventilation systems helps maintain air quality and ensures worker safety throughout the project.

Advanced Techniques Used in Warehouse Floor Resurfacing

The field of warehouse floor resurfacing has seen significant advancements in recent years, with innovative techniques and technologies being employed to overcome the challenges of busy industrial environments.

One such technique is diamond grinding, which involves using diamond-embedded grinding tools to remove the top layer of the existing floor. This process not only levels the surface but also prepares it for the application of new materials. Diamond grinding creates a smooth and uniform surface that enhances adhesion and ensures a long-lasting finish.

Another advanced technique used in warehouse floor resurfacing is shot blasting. This method involves propelling small steel balls at high speeds onto the floor’s surface, effectively removing contaminants, old coatings, and imperfections. Shot blasting leaves behind a clean and textured surface that promotes optimal adhesion of new materials.

Additionally, self-leveling overlays have become increasingly popular in warehouse floor resurfacing projects. These overlays are applied as a liquid and automatically level themselves to create a seamless and smooth surface. Self-leveling overlays offer excellent durability, chemical resistance, and aesthetic appeal.

In conclusion, warehouse floor resurfacing is an essential process for maintaining optimal functionality and safety in busy industrial environments. By assessing the condition of the floor, selecting suitable materials, planning meticulously to minimize downtime, and utilizing advanced techniques, warehouse owners can conquer the challenges associated with resurfacing projects. Investing in professional resurfacing services ensures that warehouse floors can withstand heavy traffic while providing a safe working environment for employees. So why wait? Take action today to revive your warehouse floors through expert resurfacing!

Surface Technology is a licensed industrial resin and epoxy flooring contractor, able to complete projects anywhere in the United States. We work with facility owners, design-build firms, construction management firms, and general contractors to provide industrial flooring solutions for projects in the range of 1,000 to 1,000,000+ square feet. Since 1988, we have over 35+ Years in business specializing in industrial flooring and commercial flooring services for Food and Beverage Processing, Manufacturing, Warehouse, FDA Compliance, Aircraft hangar, Vehicle Maintenance and Storage, and Pharmaceutical industries. We are experts in providing abrasion-resistant, no-slip, FDA-approved flooring for businesses.