Revolutionizing Warehouse Floor Resurfacing: Unlocking Optimal ESD Performance Trends

Warehouse floor resurfacing may not be the first thing that comes to mind when you think of innovation and technology, but the truth is, it is a crucial aspect of modern-day logistics and operations. In today’s fast-paced world, where efficiency is the name of the game, businesses are constantly looking for ways to optimize their processes and improve performance. And that’s where the concept of revolutionizing warehouse floor resurfacing comes in. When it comes to warehouse management, every detail matters. From inventory control to equipment maintenance, each component plays a vital role in the overall productivity and safety of the facility.

But one aspect that often goes unnoticed is the condition of the warehouse floor. Believe it or not, the quality of the floor surface can have a significant impact on various factors, such as worker safety, equipment longevity, and even the prevention of electrostatic discharge (ESD) incidents. That’s why the latest trends in warehouse floor resurfacing for optimal ESD performance have caught the attention of businesses across industries. ESD refers to the sudden flow of electricity between two objects, caused by a buildup of static electricity. In a warehouse setting, where sensitive electronics and materials are often present, ESD incidents can be detrimental. Not only can they damage equipment and products, but they can also put workers at risk. In this blog post, we will delve into the world of warehouse floor resurfacing, exploring the innovative techniques and materials that are revolutionizing the industry.

We will also discuss the importance of ESD performance and how optimizing the warehouse floor surface can help prevent costly incidents. So, if you’re ready to unlock the secrets to optimal ESD performance and take your warehouse operations to the next level, read on. This is a game-changer you won’t want to miss!

The Significance of Warehouse Floor Resurfacing for Modern-day Logistics

Warehouse floor resurfacing is not just a cosmetic upgrade; it plays a crucial role in the smooth functioning of modern-day logistics. The warehouse floor is subjected to constant wear and tear due to heavy equipment, foot traffic, and the movement of goods. Over time, this can lead to cracks, uneven surfaces, and deterioration, which can negatively impact overall performance.

By investing in warehouse floor resurfacing, businesses can ensure a safe and efficient working environment. A well-maintained floor surface reduces the risk of accidents caused by tripping or slipping. It also minimizes damage to equipment and products by providing a stable foundation for their movement.

Furthermore, an upgraded warehouse floor enhances productivity by enabling faster material handling operations. Smooth surfaces allow for easy maneuverability of equipment such as forklifts and pallet jacks, reducing time wastage and increasing efficiency.

Understanding the Impact of Warehouse Floor Condition on Overall Performance

The condition of the warehouse floor directly affects various aspects of overall performance. A damaged or uneven surface can result in increased maintenance costs as equipment experiences more wear and tear due to vibrations and shocks. This not only leads to frequent repairs but also reduces the lifespan of machinery.

In addition to equipment longevity, worker safety is another critical factor influenced by the warehouse floor condition. Uneven surfaces pose a significant risk of trips and falls for employees who are constantly on their feet. By maintaining a smooth and level floor through resurfacing techniques, businesses can create a safer work environment and reduce the likelihood of workplace injuries.

Moreover, an optimized warehouse floor contributes to better inventory control. With accurate tracking systems in place, businesses rely on efficient movement within the facility to maintain inventory accuracy. A damaged or deteriorating floor can hinder the smooth flow of goods, leading to errors in inventory management and potentially impacting customer satisfaction.

Why ESD Incidents Can Be Costly for Businesses

Electrostatic discharge (ESD) incidents can have severe consequences for businesses, making it crucial to address this issue through warehouse floor resurfacing. ESD occurs when there is a sudden flow of electricity between two objects due to static buildup. In a warehouse setting, where sensitive electronics and materials are present, ESD incidents can result in significant financial losses.

ESD can damage electronic components, leading to costly repairs or replacements. It can also cause data loss or corruption, impacting business operations and customer trust. Additionally, ESD incidents may result in product defects or failures, leading to returns or warranty claims.

Furthermore, ESD poses a risk to worker safety. In certain industries such as electronics manufacturing or pharmaceuticals, employees may be exposed to hazardous materials that are sensitive to static electricity. By investing in warehouse floor resurfacing techniques that minimize the risk of ESD incidents, businesses can protect their employees and avoid potential legal liabilities.

Innovative Techniques for Revolutionizing Warehouse Floor Resurfacing

The world of warehouse floor resurfacing has seen significant advancements in recent years. These innovative techniques aim to enhance the performance and durability of warehouse floors while addressing specific challenges such as ESD prevention.

One such technique is the use of specialized coatings that provide an extra layer of protection against wear and tear. These coatings are designed to withstand heavy traffic and impact while offering resistance against chemicals and abrasions. Additionally, anti-slip coatings can be applied to improve worker safety by reducing the risk of slips and falls.

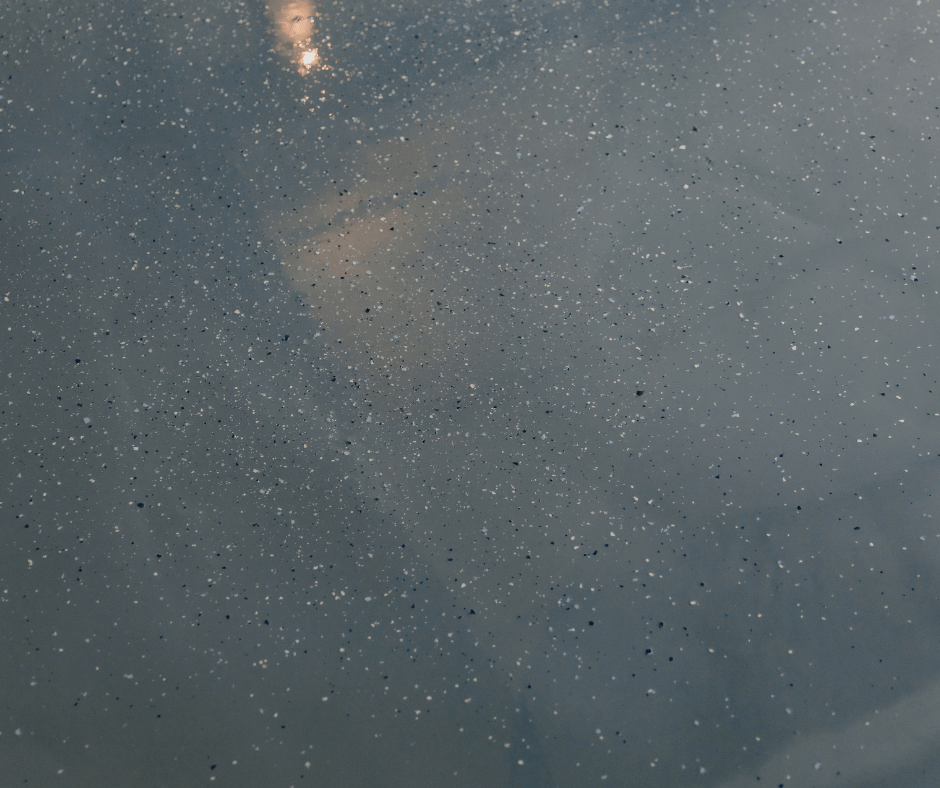

Another revolutionary approach is the integration of conductive materials into the flooring system. Conductive or static-dissipative floors help to prevent the buildup of static electricity, reducing the occurrence of ESD incidents. These floors are particularly beneficial in industries where sensitive electronic components are handled, such as electronics manufacturing or data centers.

Furthermore, advanced resurfacing techniques such as diamond grinding and shot blasting have gained popularity for their ability to restore and level uneven surfaces. These methods remove imperfections and create a smooth base for subsequent coatings or overlays.

In conclusion, warehouse floor resurfacing is a critical aspect of modern-day logistics that should not be overlooked. By investing in innovative techniques and materials, businesses can unlock optimal ESD performance trends while improving overall safety and productivity. Whether it’s preventing accidents, extending equipment lifespan, or enhancing inventory control, a well-maintained warehouse floor sets the foundation for success in today’s competitive business landscape.

Surface Technology is a licensed industrial resin and epoxy flooring contractor, able to complete projects anywhere in the United States. We work with facility owners, design-build firms, construction management firms, and general contractors to provide industrial flooring solutions for projects in the range of 1,000 to 1,000,000+ square feet. Since 1988, we have over 35+ Years in business specializing in industrial flooring and commercial flooring services for Food and Beverage Processing, Manufacturing, Warehouse, FDA Compliance, Aircraft hangar, Vehicle Maintenance and Storage, and Pharmaceutical industries. We are experts in providing abrasion-resistant, no-slip, FDA-approved flooring for businesses.