Unlocking Industry Secrets: A Comprehensive Guide to ESD Flooring Solutions

In industries and manufacturing, there’s a hidden secret that often goes unnoticed, yet plays a crucial role in ensuring the smooth and safe operations of various sectors. We’re talking about ESD flooring solutions – the unsung heroes of the industrial landscape. But what exactly is ESD flooring? And why is it so important? ESD, short for electrostatic discharge, is a phenomenon that occurs when two objects with different electrical charges come into contact, causing a sudden flow of electricity between them.

These specialized floorings are designed to prevent the accumulation and discharge of static electricity, ensuring a safe and controlled working environment. Whether it’s a semiconductor manufacturing facility, a pharmaceutical lab, or an assembly line producing sensitive electronic devices, ESD flooring is a vital component to safeguarding both the workers and the products. Now, let’s dive deeper into the world of ESD flooring solutions, uncovering the industry secrets and providing you with a comprehensive guide to understanding and implementing these innovative technological advancements. So, let’s get started and unlock the secrets behind ESD flooring!

The Importance of ESD Flooring in Industrial Environments

ESD flooring plays a crucial role in industrial environments, ensuring the safety and efficiency of operations. In this section, we will explore why ESD flooring is so important and how it contributes to the overall well-being of industries. Electrostatic Discharge (ESD) is a phenomenon that occurs when two objects with different electrical charges come into contact, resulting in a sudden flow of electricity between them. In an industrial setting, this can have severe consequences. A small spark of static electricity can ignite flammable materials or damage sensitive electronic components, leading to accidents, production delays, and potential harm to workers. To mitigate these risks, ESD flooring solutions are designed to prevent the accumulation and discharge of static electricity. These specialized floorings provide a controlled environment where static charges are safely dissipated without causing any harm. By implementing ESD flooring in industrial settings, companies can significantly reduce the likelihood of accidents and ensure the smooth operation of their facilities.

ESD flooring is particularly crucial in industries where sensitive electronic devices are manufactured or handled. For example, semiconductor manufacturing facilities require an environment free from electrostatic discharge to prevent damage to delicate microchips. Similarly, pharmaceutical labs need ESD flooring to protect sensitive drugs and chemicals from contamination caused by static electricity. Furthermore, ESD flooring also safeguards workers’ well-being by minimizing the risk of electric shocks. In industries where employees work with high-voltage equipment or handle flammable substances, having a safe working environment is paramount. ESD flooring provides an additional layer of protection against electrical hazards and helps create a secure workspace for employees. In addition to safety considerations, ESD flooring also enhances operational efficiency in industrial environments. By preventing electrostatic discharge-related incidents, companies can avoid costly production delays and equipment damage. This leads to increased productivity and reduced downtime for maintenance or repairs.In conclusion, the importance of ESD flooring in industrial environments cannot be overstated. It is a critical component in ensuring the safety of workers, protecting sensitive electronic components, and maintaining operational efficiency. By investing in ESD flooring solutions, companies can create a secure working environment that minimizes the risks associated with electrostatic discharge.

Understanding the Basics of Electrostatic Discharge

Electrostatic discharge (ESD) is a phenomenon that occurs when two objects with different electrical potentials come into contact or are near each other. This sudden flow of electricity can cause damage to sensitive electronic components, which is why understanding the basics of ESD is crucial, especially in industries where the use of electronic devices is widespread.

ESD flooring is a key component in preventing and controlling electrostatic discharge in the workplace. It is specifically designed to dissipate static electricity to the ground, ensuring the safety of both personnel and sensitive equipment. In this comprehensive guide, we will delve into the world of ESD flooring solutions, unlocking industry secrets to help you make informed choices for your specific needs.

1. What is ESD Flooring?

ESD flooring refers to a specialized type of flooring material that minimizes the accumulation and discharge of static electricity. It is commonly used in industries such as electronics manufacturing, healthcare, aerospace, and defense, where electrostatic discharge can have severe consequences.

2. How Does ESD Flooring Work?

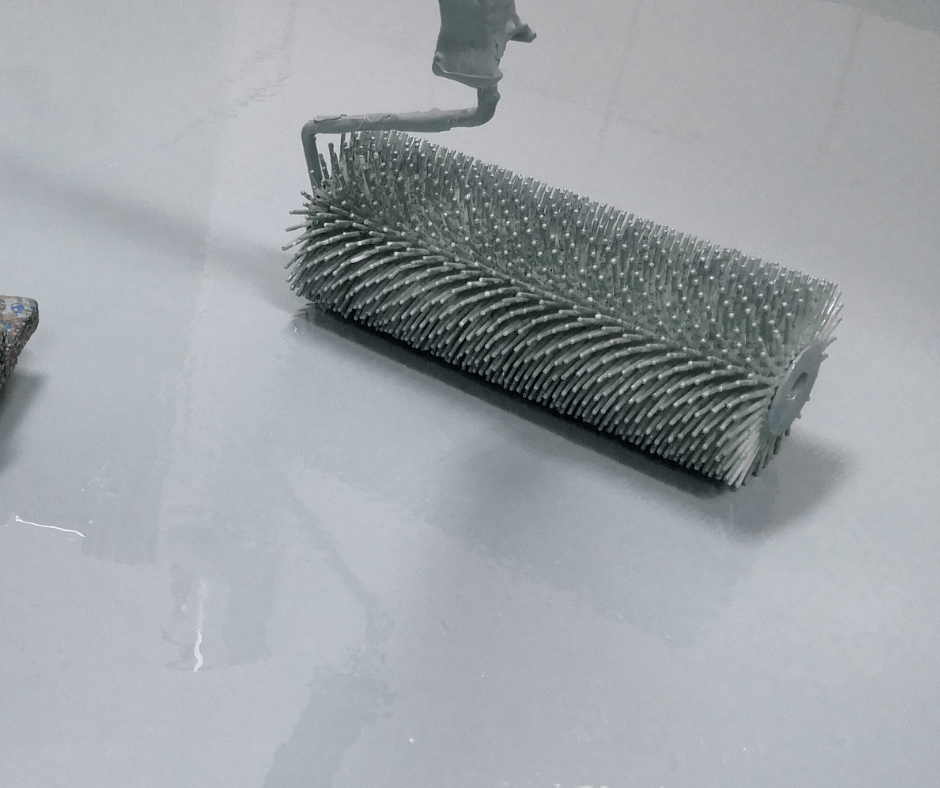

ESD flooring works by providing a conductive path for static electricity to safely dissipate to the ground. It typically consists of multiple layers, including a conductive or static-dissipative top layer, a conductive or static-dissipative middle layer, and a conductive backing layer. These layers work together to create a controlled environment that prevents the buildup of static charges.

3. Types of ESD Flooring

There are several types of ESD flooring available, each with its own unique properties and benefits. Common types include:

– Conductive Flooring: This type of flooring has a low electrical resistance, allowing the flow of electrical charges to the ground quickly and effectively. It is suitable for environments with a high risk of static discharge.

– Static-Dissipative Flooring: Static-dissipative flooring offers a higher level of electrical resistance compared to conductive flooring. It allows static charges to gradually dissipate, providing a safer environment for sensitive electronic components.

4. Factors to Consider When Choosing ESD Flooring

When selecting ESD flooring for your facility, there are several factors to consider:

– Industry Requirements: Different industries have varying ESD requirements. Understanding the specific needs of your industry will help you choose the most suitable flooring solution.

– Foot Traffic: The amount and type of foot traffic in your facility will impact the durability and maintenance requirements of the flooring.

– Chemical Resistance: If your facility deals with chemicals or liquids, it is essential to choose ESD flooring that can withstand exposure to these substances.

– Installation Process: Consider the ease of installation and any additional maintenance or grounding requirements for the chosen flooring option.

5. Maintenance and Care of ESD Flooring

Proper maintenance and care of ESD flooring are crucial to ensure its effectiveness in preventing electrostatic discharge. Regular cleaning using approved ESD-safe cleaning agents and avoiding the use of harsh chemicals are essential practices to maintain the integrity of the flooring.

In conclusion, understanding the basics of electrostatic discharge and the importance of ESD flooring is vital for industries reliant on sensitive electronic equipment. By choosing the right type of ESD flooring and implementing proper maintenance practices, you can create a safe working environment that minimizes the risk of electrostatic discharge, protecting both personnel and valuable equipment.

Common Risks and Consequences of Electrostatic Discharge in Industries

Electrostatic discharge (ESD) is a common issue in various industries, and it can have significant risks and consequences if not properly addressed. One area where ESD is particularly crucial to manage is the flooring solutions used within industrial facilities.

ESD flooring plays a vital role in preventing electrostatic discharges from damaging sensitive electronic equipment or causing harm to personnel. Understanding the common risks and consequences associated with ESD in industries can help highlight the importance of implementing effective flooring solutions.

One of the primary risks of ESD in industries is the potential damage to electronic components and devices. Electrostatic discharges can cause immediate or latent damage to sensitive electronic equipment, leading to malfunctions, reduced performance, or complete failure. This can result in costly repairs or replacements, leading to significant downtime and financial losses.

Furthermore, ESD poses risks to personnel working in industrial settings. When electrostatic discharges occur, they can cause discomfort or even injure individuals. If employees come into contact with a charged object or surface without proper grounding, they may experience a painful shock. In some cases, these shocks can be severe, leading to more serious injuries or accidents.

Aside from the immediate risks, ESD can also have long-term consequences. For instance, damaged electronic components can impact the overall quality and reliability of products manufactured in an industry. This can lead to customer dissatisfaction, decreased brand reputation, and potential legal liabilities.

Another consequence of ESD in industries is the loss of sensitive data. In sectors where data security is paramount, such as technology or finance, electrostatic discharges can corrupt or erase valuable information stored on electronic devices. This can result in data breaches, financial losses, or a compromised competitive position in the market.

To mitigate these risks and consequences, industries must invest in proper ESD flooring solutions. ESD flooring is specifically designed to dissipate static electricity safely, preventing electrostatic discharges from occurring. These specialized flooring options typically include conductive or static-dissipative properties, effectively grounding any static charges and minimizing the risks associated with ESD.

Understanding the common risks and consequences of electrostatic discharge in industries highlights the importance of implementing effective ESD flooring solutions. By investing in appropriate flooring materials and systems, industries can protect their sensitive electronic equipment, ensure the safety of their personnel, maintain product quality, and safeguard valuable data. Proactively addressing the issue of ESD can lead to improved operational efficiency, reduced downtime, and enhanced overall performance in industrial settings.

Conclusion: Ensuring Safety and Efficiency with ESD Flooring Solutions

ESD (Electrostatic Discharge) flooring solutions play a crucial role in ensuring safety and efficiency in various industries. These specialized flooring systems are designed to minimize the risk of electrostatic discharge, which can cause damage to sensitive electronic equipment and pose a threat to personnel.

When it comes to industries that deal with sensitive electronic components, such as semiconductor manufacturing, aerospace, healthcare, and electronics assembly, implementing proper ESD flooring solutions is essential. These industries handle delicate devices that can be easily damaged by even the slightest static charge.

ESD flooring solutions are engineered to dissipate static electricity and prevent the accumulation of electrostatic charges on the surface. This is achieved through the use of conductive materials that allow the controlled flow of electric charges to the ground, effectively neutralizing the risk of electrostatic discharge.

One of the key benefits of ESD flooring solutions is their ability to create a safe working environment for personnel. By minimizing the risk of electrostatic shocks, these flooring systems help prevent accidents and injuries. Additionally, ESD flooring can also reduce fatigue and discomfort caused by standing for prolonged periods, thanks to its anti-fatigue properties.

Efficiency is another important aspect that ESD flooring solutions bring to industries. By eliminating the risk of electrostatic discharge, these flooring systems safeguard sensitive electronic equipment from damage. This, in turn, reduces downtime, repairs, and replacements, leading to increased productivity and cost savings.

ESD flooring solutions come in various forms, including conductive flooring, dissipative flooring, and anti-static flooring. The choice of the right type depends on the specific requirements of the industry and the level of electrostatic protection needed.

Conductive flooring, which has a low resistance to electrical charge, is typically used in environments where the highest level of ESD protection is required. Dissipative flooring, with a higher resistance, is suitable for areas where moderate ESD protection is needed. Anti-static flooring, on the other hand, is designed to minimize static charge but may not provide the same level of protection as conductive or dissipative flooring.

It is important to note that proper installation and maintenance of ESD flooring solutions are crucial for their effectiveness. Regular testing and maintenance, in accordance with industry standards and guidelines, ensure that the flooring system continues to perform optimally and provides the desired level of electrostatic protection.

Implementing ESD flooring solutions is essential for industries that deal with sensitive electronic equipment. These systems not only ensure the safety of personnel but also contribute to increased efficiency by protecting valuable electronic devices. By choosing the right type of flooring and adhering to proper installation and maintenance practices, industries can unlock the full potential of ESD flooring solutions.

Surface Technology is a licensed industrial resin and epoxy flooring contractor, able to complete projects anywhere in the United States. We work with facility owners, design-build firms, construction management firms, and general contractors to provide industrial flooring solutions for projects in the range of 1,000 to 1,000,000+ square feet. Since 1988, we have over 35+ Years in business specializing in industrial flooring and commercial flooring services for Food and Beverage Processing, Manufacturing, Warehouse, FDA Compliance, Aircraft hangar, Vehicle Maintenance and Storage, and Pharmaceutical industries. We are experts in providing abrasion-resistant, no-slip, FDA-approved flooring for businesses.