USDA Approved Epoxy Flooring for Food & Beverage Processing Facilities

Your facility’s floor is the foundation of your operational integrity. It must do more than just exist — it must actively defend against the daily onslaught of thermal shock, harsh chemical cleaners, and heavy equipment traffic. Surface Technology provides the specialized food processing floor coatings that fortify your plant. We engineer our epoxy, urethane, and methyl methacrylate (MMA) systems to create a single, durable surface that repels contaminants, prevents slips, and withstands the most demanding conditions, safeguarding both your employees and your production schedule.

Download our whitepaper “Tips on Selecting the Right Flooring System for Food and Beverage Processing Operations.”

Surface Technology Is the Food and Beverage Processing Flooring Expert

At Surface Technology, we install high-quality seamless USDA approved flooring, coating, and lining systems for a variety of food processing applications, including:

- Dry and cold storage areas

- Mixing and canning facilities

- Meat, poultry and fish processing

- Dairy processing

- Food packaging facilities

- Bottling operations

- Seafood processing

- Sugar industry operations

- Vegetable processing

- Soft drink, wine, and beer processing plants

- Commercial bakeries

- Egg and poultry processing

- And many more

Our seamless food industry flooring solutions are USDA approved, impact resistant, easy to clean, non-toxic, antibacterials and skid-resistant for safety.

Flooring Built for Compliance and Performance

Flooring for food and beverage facilities has to perform under some of the harshest conditions in any industrial environment. In addition to withstanding forklifts, spills, temperature swings, and chemical exposure, your flooring must meet strict United States Department of Agriculture (USDA) and Food and Drug Administration (FDA) standards. That’s why our epoxy flooring for food processing facilities and urethane cement systems are engineered to handle daily operations and long-term durability.

Our food processing floor coatings can be installed with slope-to-drain designs, integral cove bases, and thermal shock-resistant layers to handle steam cleaning and washdowns without cracking. These details make the difference between flooring that causes compliance concerns and flooring that performs seamlessly for decades.

Matching the Flooring System to Your Facility’s Zone

Every food factory flooring project is unique. A bottling facility has very different requirements than a meat processing plant or a commercial bakery. That’s why we don’t use a one-size-fits-all approach. Instead, we evaluate your operation, sanitation practices, and traffic patterns before recommending the best food processing floor coatings for your environment.

We specialize in coatings for beverage facilities that demand slip resistance, easy cleanability, and high light reflectivity for improved visibility. In contrast, meat and poultry processing plants often require antimicrobial additives and impact-resistant surfaces that hold up under heavy-duty use. Our team matches the system to your exact needs, giving you confidence in long-term compliance and safety.

The choice between epoxy, urethane cement, and MMA depends entirely on factors like temperature, moisture, and traffic.

For High-Temperature and Moisture-Heavy Areas

Cook/kettle areas, pasteurization zones, and hot washdown stations create extreme thermal shock that can cause standard epoxy floors to crack and fail. Urethane Cement is the premier solution for the most demanding environments. Its unique composition allows it to expand and contract with the concrete slab, preventing delamination and preserving a hygienic, seamless surface.

For Dry Processing, Packaging, and Traffic Aisles

These areas require high durability against forklift traffic, abrasion, and chemical spills, but do not experience the same level of thermal shock. High-Solids Epoxy Flooring is the durable, cost-effective workhorse for these zones. It has excellent abrasion resistance and is easy to clean.

For Projects Requiring Minimal Downtime

Many food and beverage plants operate 24/7, and downtime for facility upgrades must be minimized or eliminated. MMA flooring is the fastest-curing system. It can be fully cured and ready for service in as little as one hour per coat, making it the ultimate solution for rapid repairs or weekend installations.

The Team Behind America’s Food Factory Flooring

As a leading resin flooring installation contractor since 1988, Surface Technology has earned a solid reputation for superior quality solutions. In fact, many nationally recognized brands have entrusted us with epoxy flooring for food processing and food and beverage flooring installations across the United States.

We have been recognized by national publications, trade associations, and construction professionals as a performance and quality leader among flooring contractors. We regularly partner with facility owners, design-build firms, construction managers, and general contractors to provide food factory flooring solutions for projects ranging from 1,000 to more than 1,000,000 square feet.

See The Results for Yourself

From Paragon Foods to Lancaster Cupcakes, our project portfolio showcases how we’ve transformed facilities with seamless, hygienic food and beverage flooring solutions. These case studies highlight how the right food processing floor coatings improve sanitation, worker safety, and overall efficiency. Explore our success stories and watch our project videos to see the difference high-quality USDA-approved flooring can make in your facility.

Like what you see? Request a quick quote today and see the results for yourself.

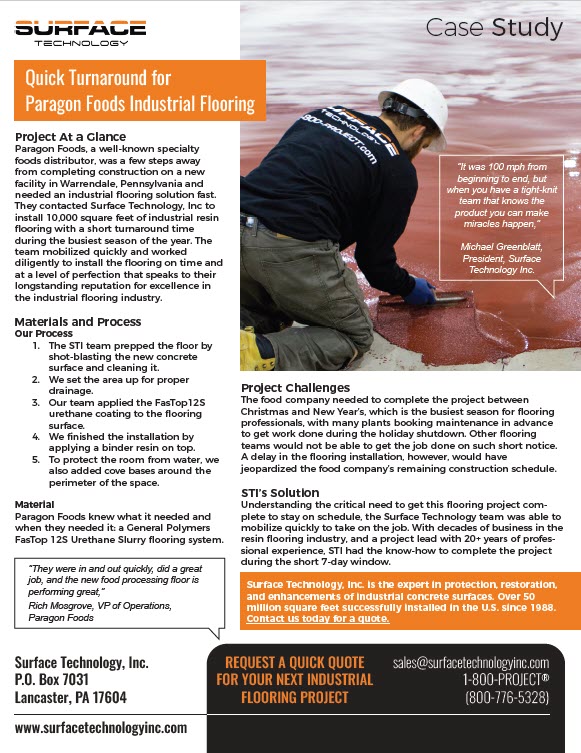

Paragon Foods, a well-known specialty foods distributor, hired STI to install 10,000 sq. ft of industrial resin flooring with a short turnaround time.

Lancaster Cupcake, a renowed bakery, reaced out to STI for a much-needed update to their back kitchen flooring.

Get in Touch

We know you’re busy. We’re here to get you the information you need as quickly as possible. Whether you just want a quick estimation on your project specifications or want to talk to an expert about your project, we are here to help you.